About Segmented Blade Clarifiers

Settled sludge is directed to the center by multiple blades pushing the sludge to the center over multiple passes of the rake arm.

Raking blades turned at an approximately 45-degree angle are supported from two structural support arms. The settled sludge is plowed inward from one blade to another until it is deposited into a sludge pit.

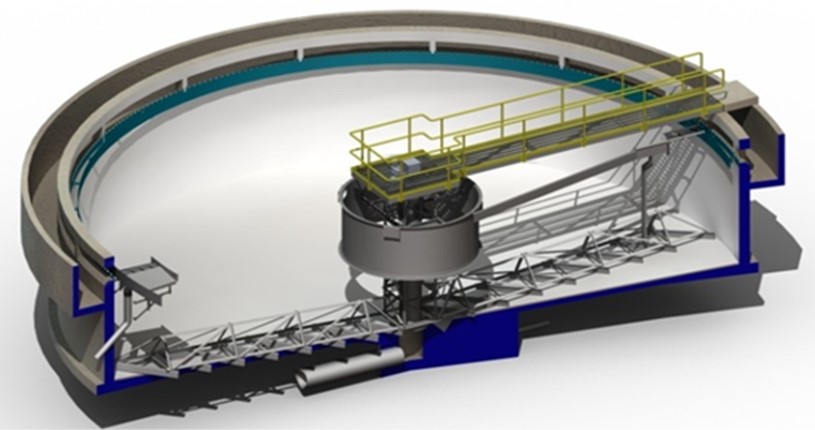

3D Models of Every Project

ClearStream produces a 3D model of every unit which we manufacture. These models are extremely valuable to ensure proper fit up. In addition, these models can be a useful tool for operators training and understanding of the unit design and operation. ClearStream provides these 3D models as well as the means for clients to view and manipulate these models at their own site or offices. This affords operations and maintenance personnel with a unique opportunity to “inspect” the unit prior to any planned maintenance without having to drain the tank.

Advantages:

- Simple design.

- Nothing to “plug up” under water.

- Regardless of solids loading settled sludge will be transported

to the sludge pit.

Disadvantages:

- Sludge transport from the outside may take many hours, especially on

large (>100’ diameter) units, leading to the potential of septicity. - Under high flows and/or high solids loading conditions, the raking

mechanism may not be able to transport solids as quickly as they are

settling, causing a buildup of solids in the basin. The deeper sludge

blanket can lead to scouring and short circuiting.

Variations:

- Change to the angle of the blade to the radius.

- Increase the depth of all the blades.

- Increase the depth of each blade as it gets nearer to the center and

settle sludge sump. - Add two more half radius arms to aid in solids transport for clarifiers larger than 100’ diameter.

Have A Process Problem? Need A Solution?

Our engineers will ensure you get the support needed to solve your process problems.