About Solid Contact Clarifiers

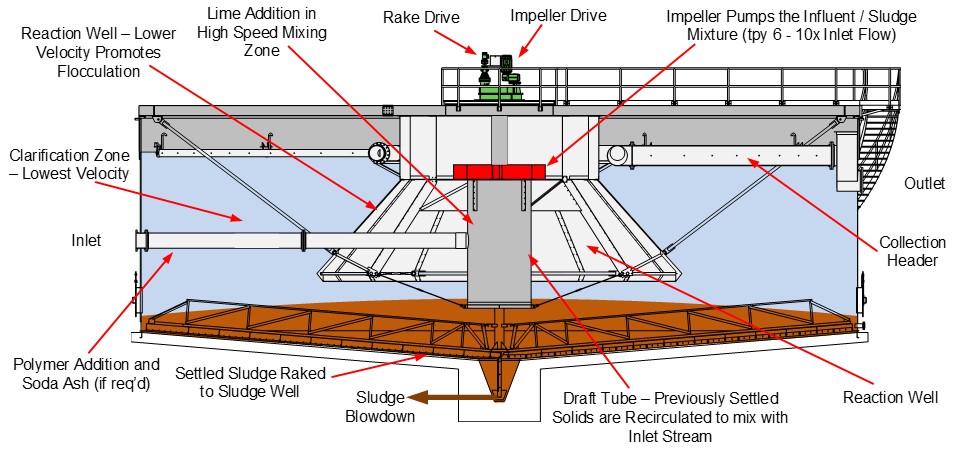

Solids contact clarifiers combine the process of mixing, flocculation and sedimentation in a single tank. Recirculation of solids and mixing is accomplished by a radial or axial impeller. Flocculation occurs within the reaction well.

Sedimentation occurs in the clarification zone. The clarifier is comprised of a mixing zone, flocculation (reaction) zone, sludge blanket zone, and a clarification zone. An impeller draws concentrated settled solids from the bottom and mixes them with the lower solids concentration influent and disperses it into the reaction well.

Solids Contact Clarifiers are typically used in water softening and color and turbidity removal clarifiers in water treatment plants and polishing or tertiary clarifiers in wastewater treatment plants. Solids Contact Clarifiers are particularly advantageous in lime softening of groundwater since the precipitated solids help speed the flow, growing larger crystals of precipitate to provide a thicker waste sludge.

Solids Contact Clarifiers have also been applied in the chemical treatment of industrial wastes such as metals removal and used successfully for cooling tower make up water.

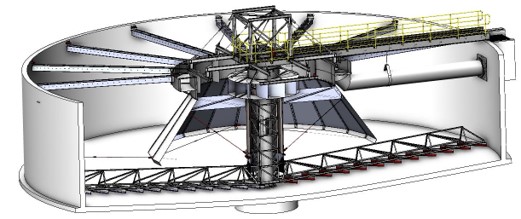

3D Models of Every Project

ClearStream produces a 3D model of every unit which we manufacture. These models are extremely valuable to ensure proper fit up. In addition, these models can be a useful tool for operators training and understanding of the unit design and operation. ClearStream provides these 3D models as well as the means for clients to view and manipulate these models at their own site or offices. This affords operations and maintenance personnel with a unique opportunity to “inspect” the unit prior to any planned maintenance without having to drain the tank.

Advantages:

- Internal sludge recycle.

- Excellent for chemical perception.

- Can achieve clarity on low solid feed streams.

- Optimum use of chemicals.

- Added “Filtration” when operated with sludge blanket.

Disadvantages:

- Highest capital cost of all clarifier designs.

Have A Process Problem? Need A Solution?

Our engineers will ensure you get the support needed to solve your process problems.