Consol Energy — Knight AMD Treatment Facility

High Density Sludge (HDS) System Treating 1,700 GPM of Acid Mine Drainage

Industry: Mining Water & Wastewater Treatment

Location: Mannington, West Virginia

Application: Acid Mine Drainage (AMD) Treatment

Technology: High Density Sludge (HDS) + Sludge Thickening

Project Overview

The Consol Energy Knight AMD Treatment Facility treats up to 1,700 gallons per minute of acid mine drainage using a proven High Density Sludge (HDS) treatment process. Acid mine drainage often exhibits very low pH values—sometimes near 2.0—and contains dissolved metals such as iron that must be oxidized and removed before discharge.

The treatment process begins with aeration of the raw influent to remove carbon dioxide. Reducing CO₂ naturally increases pH and introduces oxygen, allowing dissolved iron to oxidize and convert to a form that can be removed from solution.

A mixture of recycled sludge conditioned with fresh lime is added to the stream. This step forms a dense sludge that settles efficiently while also increasing the pH. Polymer is added to promote rapid floc formation and enhance solids separation.

Thickening & Sludge Recycle System

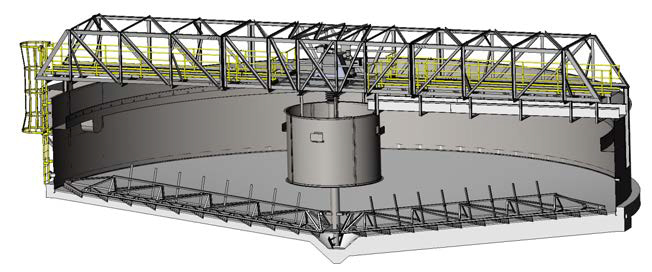

The treated water and solids enter a 70-foot diameter ClearStream Thickener with lift-style shaft drive designed specifically for AMD and HDS applications. The thickener includes pickets mounted to the rake arms, which create drainage channels in the sludge blanket to improve compaction and release additional water.

If high-torque loading occurs, the automatic lift mechanism raises the rake structure to protect equipment and alerts the operator so conditions can be addressed proactively.

Settled sludge is pumped from the thickener underflow. A portion is recycled back to the HDS process tank, where it is blended with lime slurry and returned to the system inlet. The remaining sludge is pumped to disposal, typically into abandoned mine areas. This sludge recycle loop increases density, improves settling, and reduces lime consumption—making HDS a cost-effective AMD treatment solution.

Results

The clarifier effluent commonly contains 10 ppm (or less) of suspended solids, producing water suitable for compliant discharge while reliably managing high-volume AMD flows.

ClearStream also develops 3D equipment models for each thickener system. These models support accurate fabrication, seamless installation coordination, and improved operator training and system understanding.

Equipment Highlight

70′ Diameter ClearStream HDS Thickener with Lift & Picket Rakes

-

Designed for acid mine drainage treatment

-

High-torque protection with automatic rake lift

-

Picket rakes enhance sludge compaction and thickening

-

Engineered for dependable mining and industrial applications

Resources and Related Links

![]()

Consol Energy — Knight AMD Treatment Facility