Engineered Biological Treatment You Can Trust

ClearStream delivers proven biological process equipment and turnkey biological treatment systems for municipal and industrial wastewater. Our ClearFlo product family—jet aerators, Continuous Loop Reactors (CLR), Sequencing Batch Reactors (SBR), and Bullseye bio-treatment channels—is engineered for high process performance, low maintenance, and flexible configuration to meet strict effluent targets and retrofit demands.

Core Technologies & What They Do

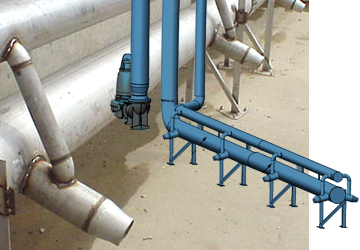

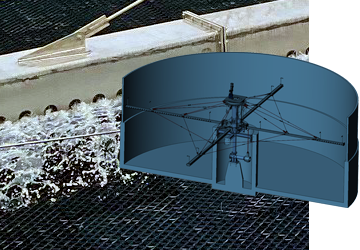

ClearFlo™ Jet Aerators

Independent control of oxygen and mixing

ClearFlo jet aerators separate motive (mixing) flow from gassed (oxygen) flow so oxygen transfer and mixing are controlled independently. This allows precise process control, anoxic operation for nutrient removal, and operation without surface mist or spray (reduced odors and VOCs). Benefits include high oxygen transfer efficiency in “dirty water,” thermal conservation for year-round nitrification / denitrification, and low maintenance — periodic five-minute backflush is the only routine required.

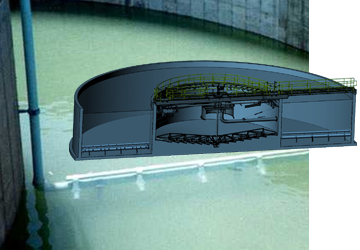

ClearFlo™ Continuous Loop Reactors (CLR)

Space-efficient BNR/CLR systems

CLR systems are optimized for biological nutrient removal and compact footprints. Deeper basins reduce heat loss and improve winter performance; subsurface jet aeration eliminates splash and mist, lowers maintenance (no shafts/disks/gear drives), and provides long service life. CLR configurations support single stage, dual stage, and full BNR operation.

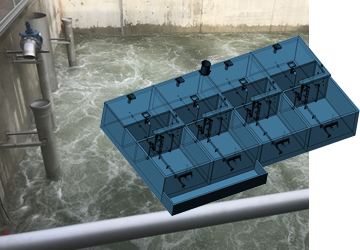

ClearFlo™ Sequencing Batch Reactors (SBR)

Flexible, state-of-the-art SBR designs

ClearFlo SBRs are available in packaged or large constant-level formats and are capable of handling flows from zero up to 350% of design flow without bypass or permit violations (proprietary operating strategy). SBRs support aerobic/anoxic/anaerobic sequencing and are available as turnkey packaged plants.

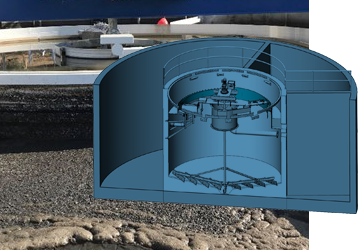

ClearFlo™ Bullseye Bio-Treatment Channel

Full spectrum in a single unit

The Bullseye channel combines equalization, aerobic, anoxic, anaerobic, chlorination, aerobic sludge storage, and central clarifier in a common-wall tank to reduce footprint and installation cost. The central clarifier can use segmented or spiral blade technologies and includes flexible drive options.

ClearFlo™ Trickling Filters & Media Support

Robust biological polishing

ClearStream offers trickling filter configurations, distributors with speed control and media flushing capability, and optional recirculation for flow balancing and odor control. These options are suited for facilities wanting fixed-film solutions for secondary treatment or polishing.

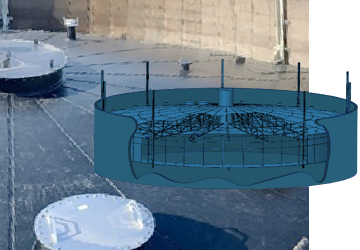

Digester Covers & Ancillaries

Engineered Digester Covers for reliable gas control

Complete digester cover solutions (gasholder, floating truss, dual membrane, slab/tank mounted) and ancillary equipment (backsflush headers, valves, clarifier blades, scum skimmers) are available to deliver full process packages.

Key Performance &

Design Highlights

- Independent mixing & aeration control — set oxygen delivery (10–80 SCFM per jet aerator range) separately from mixing to optimize nitrification/denitrification and settling.

- Highest oxygen transfer efficiency in dirty water — engineered for real process conditions to maximize oxygen transfer where sludge/solids are present.

- No mist, spray, or splash — cleaner walkways, reduced odor emissions and airborne VOCs.

- Thermal conservation — submerged airborne release and lack of surface splash reduce freezing risk and support year-round biological operation.

- Low routine maintenance — simple five-minute backflush is standard maintenance on jet aeration systems.

Representative CLR process parameters

(typical design targets):

- MLSS: 3,000 – 5,000 mg/L

- Hydraulic Retention Time (CLR): 24–48 hours

- Typical effluent goals: BOD₅ < 10 mg/L

- TSS < 10 mg/L, Total N < 5 mg/L

- NH₃-N < 1 mg/L (site-dependent).

Applications & Industries

- Municipal wastewater treatment (small towns to mid-size cities)

-

Industrial wastewater — food & beverage, textiles/dyeing, laundry, chemical process streams

- Retrofit & upgrade projects where operator simplicity, low maintenance, and footprint reduction are priorities

- Decentralized and packaged plants for remote or constrained sites

All systems are designed for ease of operation and straightforward maintenance, making them attractive for owner-operators seeking reliable performance with lower O&M burden.

Why ClearStream Biological Systems?

- Proven process control — independent aeration/mixing control enables optimized biological performance and improved nutrient removal.

- Reliable, low-maintenance equipment — long service life with simpler maintenance compared to many mechanical surface aerators or complex gear-driven systems.

- Compact, modular options — suitable for space-constrained sites and easier retrofits.

- Turnkey capability — engineering, fabrication, installation, start-up and service support for full project delivery.

Continue to explore

Case Studies

Let’s Solve Your Process Treatment Challenge

+1 801 676 1890

info@clearstreameng.com

Speak with a ClearStream engineer about your process needs. We’ll help you identify the best solution for your system and application.